In the spotlight: Zooming in on lustrous corrosion-resistant zinc alloy hardware

In ancient times, zinc metal products—including knobs and pulls— have been increasingly launched in large scale of applications all over the world (communication equipment, musical instruments and home furniture hardware). Interestingly, zinc derived from the Orient and was regularly imported to Europe in the 17th and early 18th centuries. (The intriguing information is retrieved from International Zinc Association)

Nowadays, zinc is known for its fourth most common metal in use, trailing behind only iron, aluminum and copper with the production of about 10 megatons once a year. Zinc, mixed with other metal alloys, now is commercially employed in large-scale applications, especially in furniture hardware.

Galvanization (a kind of metal special treatment)—meaning zinc is coated on the iron or steel home furniture hardware—is popularly used as an anti-corrosion agent to protect builder hardware from corroding away slowly and damages, compared to those of ferrous hardware without an anti-rust layer. This protection layer lasts even longer than that of ferrous hardware or other rust-triggered metal hardware for furniture (drawer pull hardware or door knob hardware). Imagine a situation, a strong corrosion-resistant zinc property attached to a ships’ iron keel makes it useful in protecting zinc alloy metals exposed to sea water from rust. Similarly, the superb zinc alloy coating attached on the surface of cabinet hardware or drawer hardware would be a terrific protective guard for home furniture hardware.

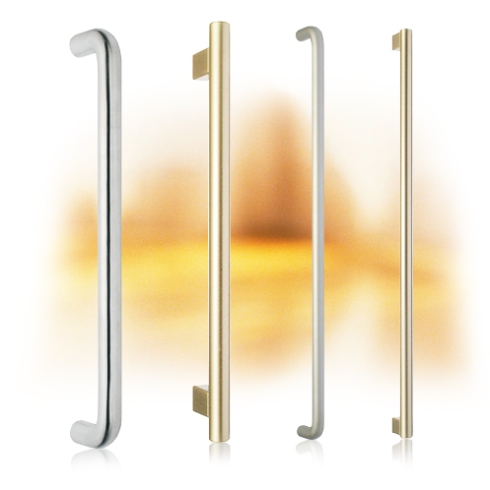

The below door pulls or drawer knobs, coated with primarily zinc and other minor-percent amounts of copper, aluminum and the like, make the zinc alloy pulls and knobs, like zinc aluminum ones, have superior corrosion resistance and malleability; what’s more, zinc alloy knobs and hardware pulls give the vivid impression of a lustrous texture and intricate shape

Key words:

Knobs and Pulls, home furniture hardware, hardware, zinc, knobs and pulls, furniture hardware, builder hardware, hardware for furniture, drawer pull hardware, door knob hardware, door pulls, drawer knobs, pulls and knobs, knobs, hardware pulls, cabinet hardware, drawer hardware